Easy to Install Waterproof Acrylic Tub Surround

How to Install a Bathtub: Install an Acrylic Tub and Tub Surround

Updated: Jun. 07, 2022

Remove an old plastic bathtub and surround and install a new bathtub and three piece surround with new plumbing and a tile border.

In this story, we'll walk you through a basic installation process, beginning with what is often the toughest part—tearing out the old tub and shower. Then we'll show you how to install and replumb the new unit. And finally, we'll show you a tiling technique that simplifies the finish work and makes the entire installation look great.

You might also like: TBD

- Time

- Complexity

- Cost

- Multiple Days

- Intermediate

- $501-1000

Planning

An acrylic tub and shower surround may not have the sex appeal of an enameled cast iron tub and an elegant ceramic tile surround, but it's a lot easier to keep clean and looking spotless. It wipes off quickly and has few joints to catch mold-attracting dirt and scum. And the unit is much easier to install. Most models consist of a tub plus three shower wall panels, which all interlock and seal. It's the perfect item for a weekend bathroom upgrade. (OK, a full weekend.)

In this story, we'll walk you through a basic installation process, beginning with what is often the toughest part—tearing out the old tub and shower. Then we'll show you how to install and replumb the new shower. And finally, we'll show you a tiling technique that simplifies the finish work and makes the entire installation look great.

This project is a bit complex for a beginner. You should have some experience working with plumbing (P-traps and/or faucets) and basic carpentry tools. If you replace the shower valve and have copper supply lines, you'll need soldering skills. Our tub/shower unit cost $300 ("Acclaim" by Sterling), and other materials (new shower valve, tile, etc.) cost about $200. This price tag could easily double with a higher priced tub and surround and fancier valves. If you do it yourself, you'll save the $1,000 cost of professional installation.

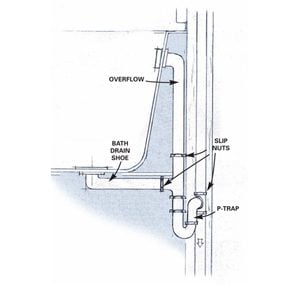

Begin by measuring the approximate length and width of your existing bathtub. Allow about 3/4 in. extra at each wall and your measurement should be close to one of the standard tub sizes. Most are 5 ft. long and 30 in. wide and are designed to fit against the wall studs (Figure A). Then shop for tubs and surrounds at home centers or kitchen and bath specialty stores. Then order your tub. Acrylic replacement tubs are light enough for one person to lift in and out, even in tight spaces. But beware of one piece bathtub shower surrounds and one-piece tub/shower stalls. They're usually too bulky to get into an existing bathroom. Also pick up a new drain and overflow assembly (Figure B), clear silicone kitchen/bath caulk and the other materials shown in the photos. This is also the perfect time to replace the old shower valve, spout and shower arm.

Remove the tub faucet and shower head

Before beginning, spread a thick canvas dropcloth over the bathroom floor and any nearby fixtures. Find the shutoffs for the tub—usually behind an access panel in an adjacent room—and turn off the water. Then turn the tub faucet on to make sure the shutoffs actually work. If water continues to drip out, turn off the main water supply and replace the shutoffs. (Here are details on replacing the shutoff valves.) Now remove the faucet hardware (Photo 1). Most faucets are held by screws. Look for an Allen screw in a recess under the tub spout. If it doesn't have one, it's probably a spout that you unscrew (counterclockwise) with a pipe wrench. Wrap a rag around the jaws if you're planning to save or reuse the spout. Unscrew the shower arm with the pipe wrench too.

Tear out the old bathtub surround

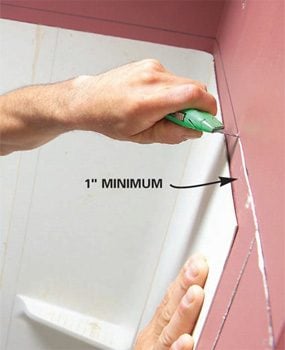

To reduce hassles later, check the dimensions of the new tub surround (including the nailing flanges) before you cut out the old surround or tile wall. Then make your cuts about 1 in. larger than the "rough-in" dimensions of the new tub surround (Photo 2). Cut through the drywall around the tub and down to the base trim. Cover or disconnect the tub drain to keep the waste line from filling with debris. The utility knife scoring method we show takes some strength, but it avoids the problem of cutting into insulation and hidden wires and pipes. If you use a drywall or keyhole saw, cut carefully and keep the cut shallow.

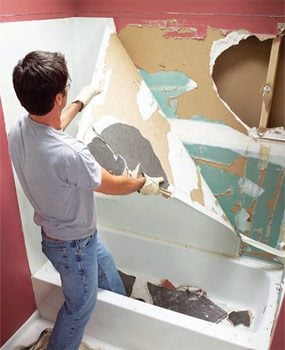

Many older tub surrounds are glued to drywall, as ours was. If so, pull out the old drywall and surround with a hammer, pry bar and your hands, starting at the top and working down (Photos 3a, b, c and d). This also works for tile over drywall or backer board. Wear a dust mask if the drywall is moldy or you're destroying old plaster. If the old surround was screwed into place, simply back out the screws.

Remove the old bathtub

To disconnect the drain lines, remove the access panel in the neighboring room that gives access to the plumbing. Unscrew the tub drain and overflow where it joins the P-trap (Photo 4 and Figure B). If the old waste and overflow connections are stuck, cut them with a reciprocating saw or hacksaw and unscrew the stubs later when the tub is out. Replace old metal traps with new plastic ones. If you plan to replace the shower valve, remove it now.

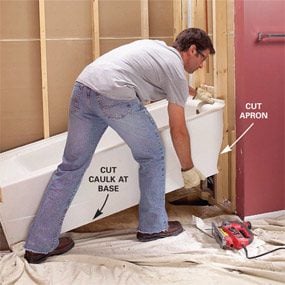

It's usually hard to get an old tub out in one piece. With a fiberglass or acrylic tub, cut out a chunk with a jigsaw and lift out the tub (Photo 5). Steel tubs are tougher; you may have to remove drywall and slide them out, although you can often tip them up and out too. Cast iron tubs are too heavy to lift out. Break it up with a sledge. You have to slide in new cast iron tubs.

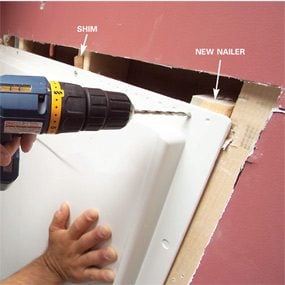

Remove any moldy insulation and add new 2×4 nailers as needed to support drywall edges and the new tile backer that you'll add later (Photo 6). Anchor these with screws driven through the drywall. It's not usually necessary to nail them to solid framing. But don't add nailers at the drain end of the tub until the new tub is in. You may need the extra wall space when you're tipping in the new tub.

If you have mold, scrub it away and let the area dry thoroughly before covering it with insulation and a vapor barrier.

How to replace a bathtub

Unpack the new tub and set it into place. Before you begin the bathtub installation, check the tub rim for level, both front to back and side to side (Photo 7). The nailing flanges on plastic tubs are not meant to bear weight, so the tub legs must have solid, level bearing on the floor. Shim spaces less than 1/2 in. with hardwood, metal or plastic spacers (don't use softwood for tubs with small legs because the wood will crush). For thicker shims, use boards or strips of plywood. Use wide spacers and nail or glue them into place at the leg locations so they won't shift when the tub goes in. On larger tubs, the manufacturer may ask you to set the tub in a wet mortar bed, which will mold to the tub bottom and provide extra support.

At this point, note how the apron (outer edge) of your new tub meets the existing floor. Now's the time to plan this joint, while you can still remove the tub. If you're lucky, the new tub will meet the floor almost like the old one. But you may have a larger gap, or you may have to trim back the finish flooring to get the tub to fit. Solutions vary with the type of floor you have and the gap size. One solution for a gap is to cover the joint with a thin solid-surface or marble threshold strip. Use silicone to glue it to the tub or floor, and caulk the edges along the tub and floor.

Before installing the tub, add the new drain shoe while it's still easy to get at (Figure B). Lay a thick ring of clear silicone caulk under the rim, and screw it together following the tub manufacturer's instructions.

Then install the bathtub and anchor it to the wall studs as recommended by the manufacturer. Our bathtub used special attachment clips, which we fastened with roofing nails driven just above the flange (Photo 8).

Tip: Protect your Tub

Make sure to protect the finish of your new tub with paper or cardboard while you're working. And keep it free of grit and debris.

How to install the surround

Set the back section of the surround on the tub rim, holding it in place temporarily with a nail above the top flange. Then set the side panels (Photo 9). The manufacturers allow a little play here, but not much. Chisel back any warped or out-of-plumb studs to keep the panels sitting flat on the tub rim. You can add a shim later if you find a gap (Photo 11). This is where setting your bathtub perfectly level pays off! The panels should align within about 1/8 in. If not, recheck your tub for level.

Center the new shower valve on the tub, and solder it in place at the recommended distance back from the finished wall (Photo 10). You may have to shift an old valve in or out to fit the new surround.

Reset the back panel and measure to the centers of the valve and the tub spout. Take these measurements twice! Mark those points on the end panel and cut the holes. Hole saws make the cleanest cuts, but you can also make the cuts with a sharp 1-in. spade bit or a jigsaw (from the back side).

Set the surround panels, locking the corners. If the tops of the panels are within 1/8 in. of each other, tap the high panel down gently with a rubber mallet. Otherwise, rework the tub leveling or shave wall studs to get a more perfect fit.

Anchor the panels to the wall with the fasteners specified by the manufacturer. Drive them through slightly oversized predrilled holes (Photo 11). Follow the manufacturer's instructions for caulking.

Finish the walls around the tub

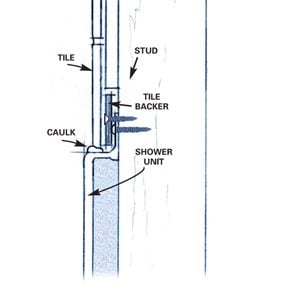

Making a nice wall finish around the new surround requires special attention to detail. Because of the thickness of the flange, use 3/8- or 1/4-in. backer board to keep the surface flush with the drywall (Photo 12). In addition, we chose to tile around all the edges to cover the joint and avoid a difficult taping job. The thin backer board is fragile in narrow strips; predrill and fasten it to the studs with the special screws designed for backer board. Hold it back about 1/8 in. from the edge of the surround (Figure C).

Clean and prime painted walls before tiling. Then set the tile, working from the outside corners on the end walls and from the center on the back wall for a symmetrical layout (Photo 13). Caulk the tile/tub joint the day after you grout.

Install the finished plumbing

Now finish the plumbing. Spread a bead of silicone around the edge of each hole in the surround and install the faucet plate and tub spout. (Avoid bowing the surround inward when tightening.) Cut the new drain line and overflow to length and hook them up to the P-trap and tub. Then run water into the tub to test for leaks.

Editor's Note: Dealing with Old Pipes

Finding old steel pipe in the wall doesn't mean you have to replumb the entire house. You can make a transition from galvanized water supply pipe to copper or plastic (CPVC). For copper, use a special dielectric coupling—a fitting that prevents corrosion. If you have steel drainpipes, use a special "mission coupling" for transitions to plastic drains. All these fittings are available at hardware stores and home centers in many sizes.

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you'll save time and frustration.

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here's a list.

Originally Published: November 29, 2018

Source: https://www.familyhandyman.com/project/install-an-acrylic-tub-and-tub-surround/

0 Response to "Easy to Install Waterproof Acrylic Tub Surround"

Post a Comment